AVS

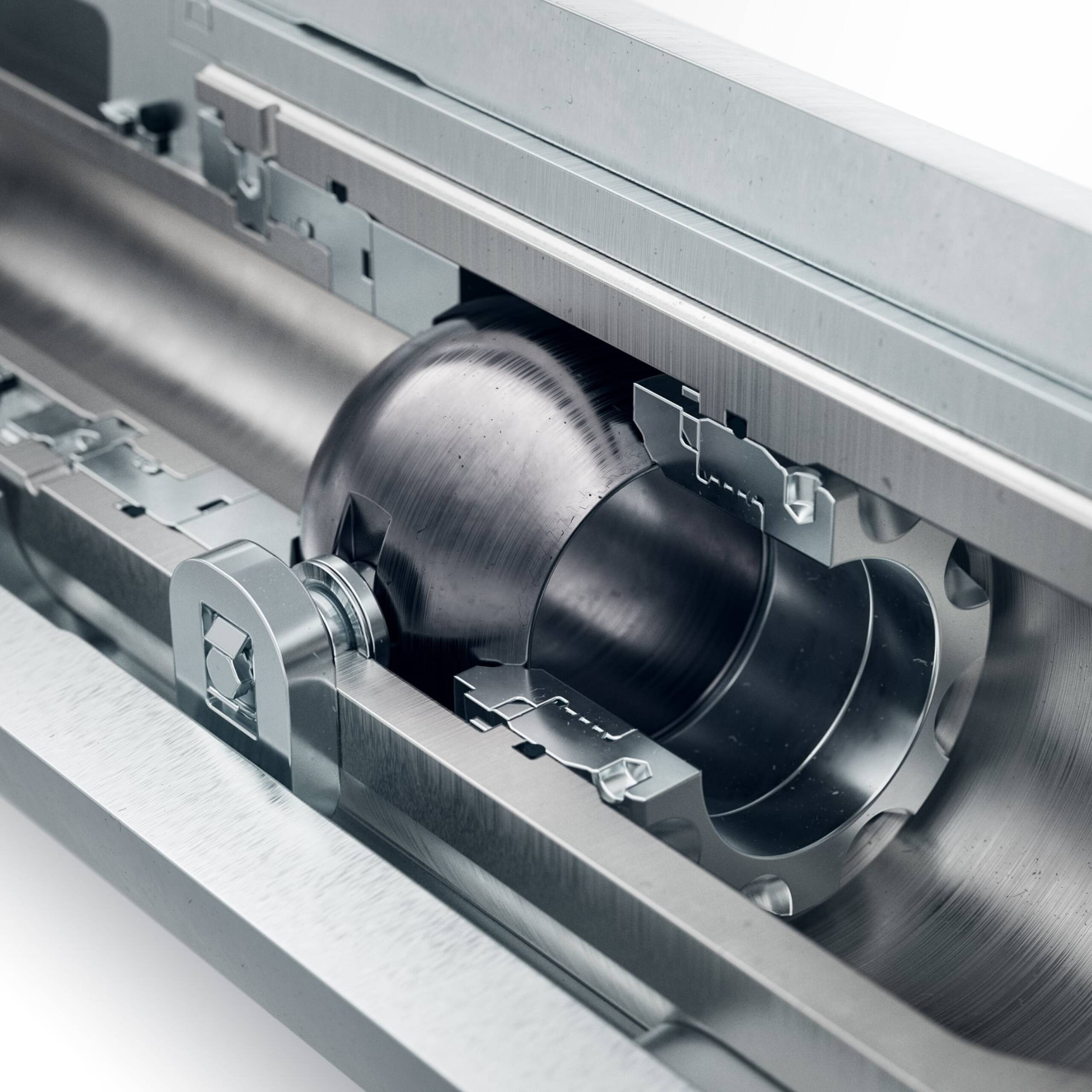

The AVS is a DEAP activated Multi-position, Multi-cycle Flow Divertor. It can be run anywhere in the drillstring or BHA, even below an MWD as there are no balls or darts to drop to activate. It has 3 positions; Thru-bore, Splitflow for Hole Cleaning While Drilling and Full Bypass for LCM dump or rapid well