DEAP Module

This totally replaces the need to drop balls, darts, electronic tags or anything down the drillpipe or tubing to activate a downhole tool such as a circulating sub, reamer, packer or anything that previously required a ball or some such device to activate.

The DEAP module contains various sensors that can be programmed using the DEAP V2 Software. The Activation Protocol can be a sequence of RPM, Pump Cycles, Pressure differential or a combination of all. The activation protocol could also be various durations of parameters. Whichever is most suitable to the well application.

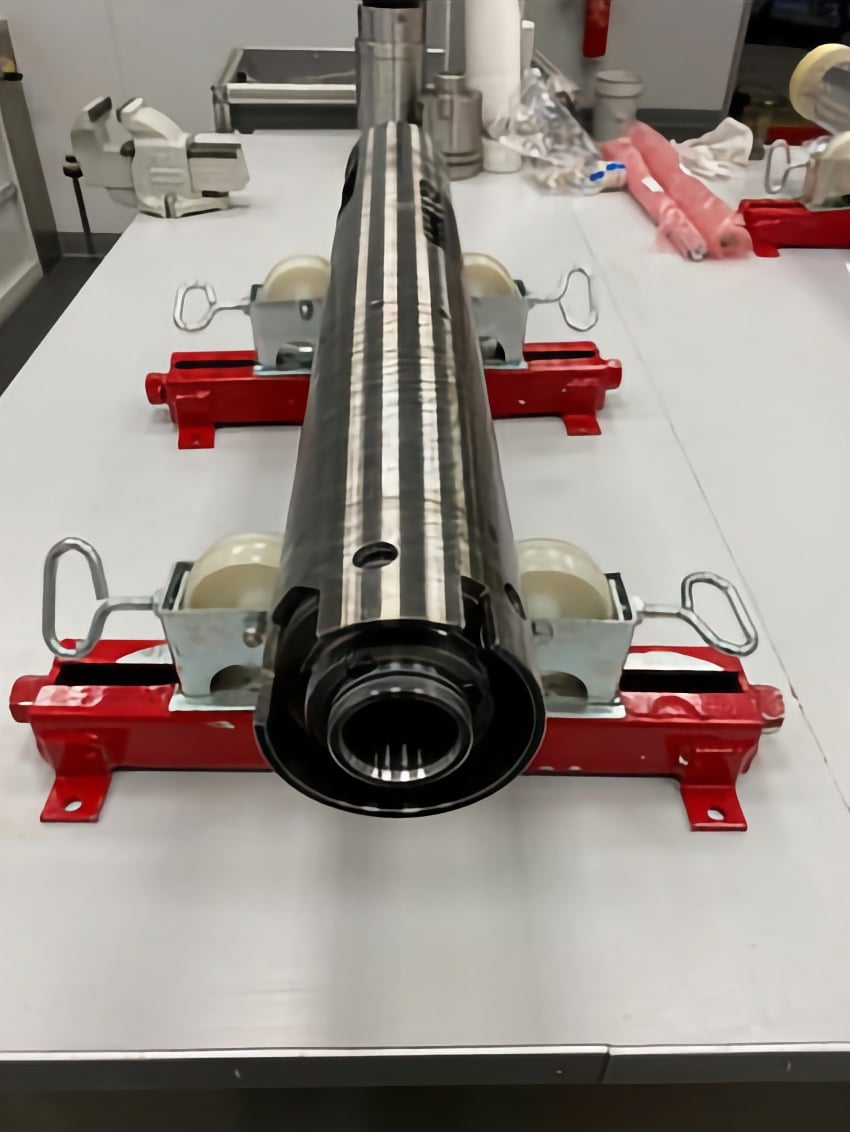

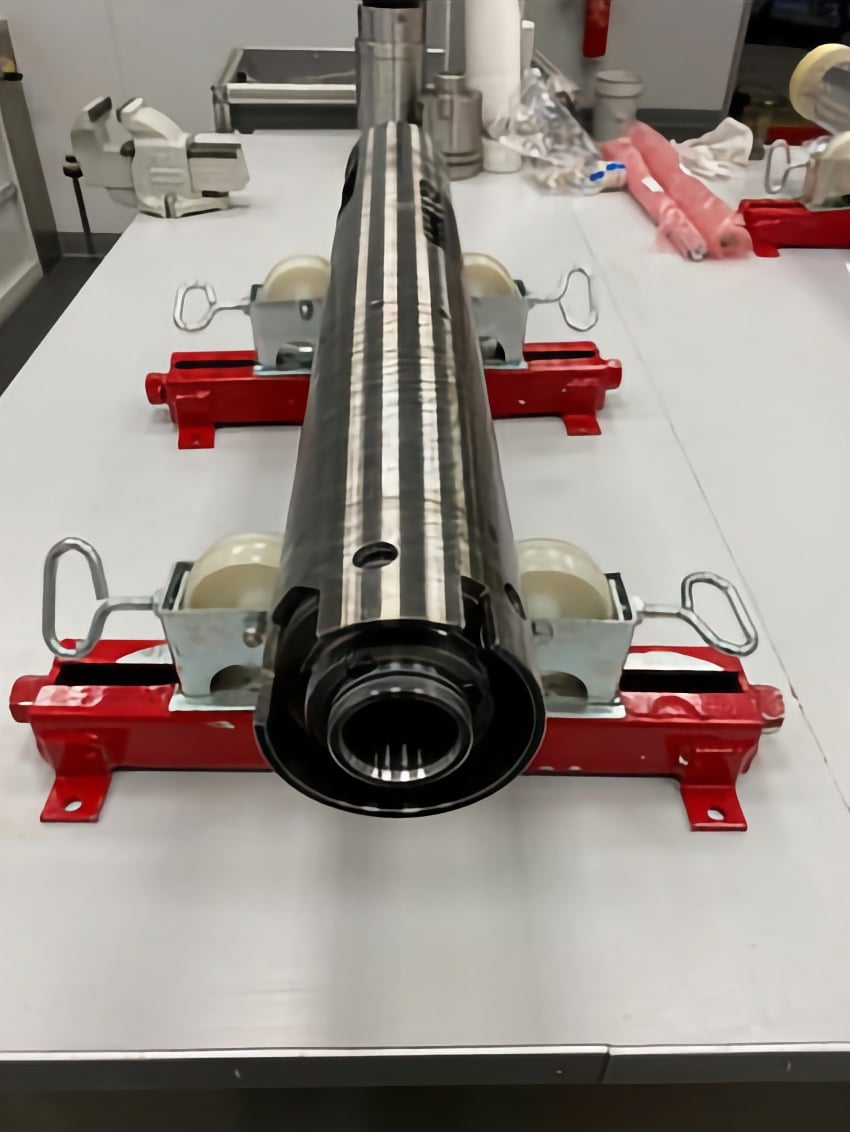

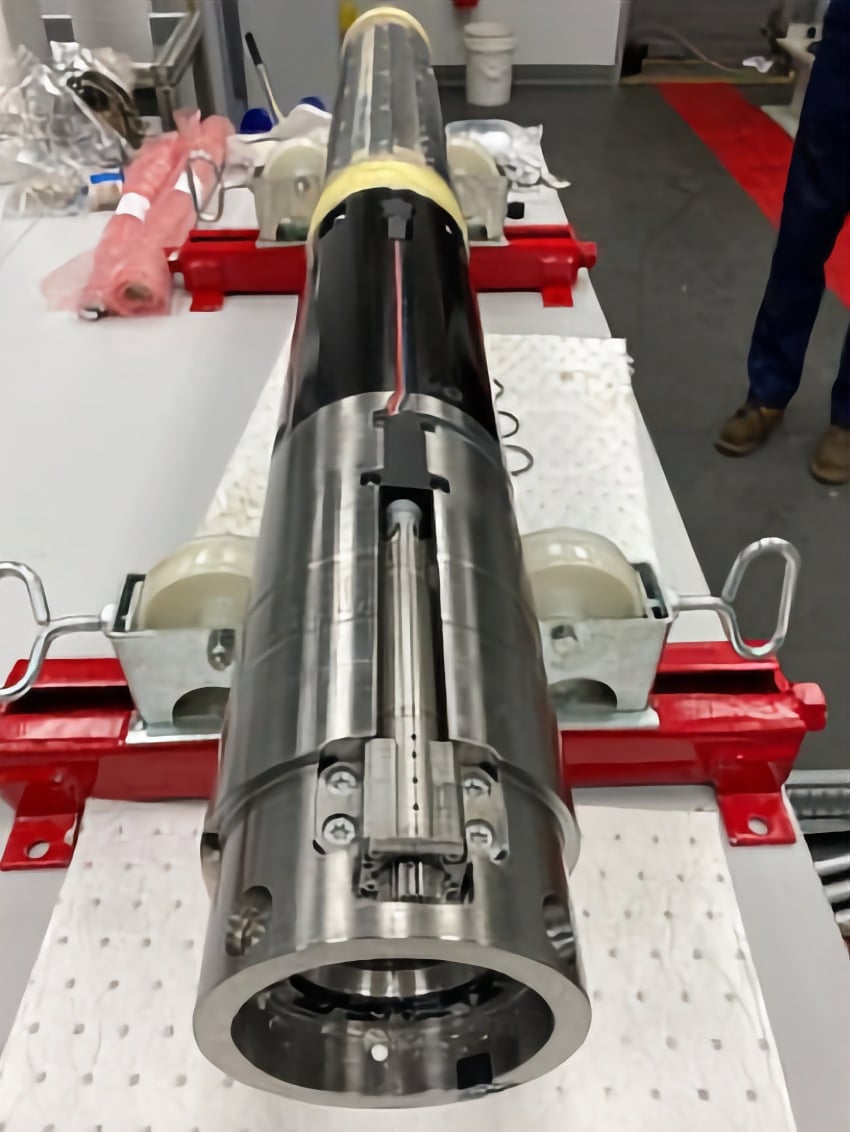

The DEAP Module can be attached to the “tool” that needs activated. In the photos there is a DEAP module which has been designed to fit the AVS module.

DEAP Module

AVS Module

This is extremely versatile and almost any parameter can be programmed into the tool to effect and activation. The most common and simplest are using the internal MEMS gyro for RPM and Pump cycles. Some examples of Activation protocols are given below”

This is extremely versatile and almost any parameter can be programmed into the tool to effect and activation. The most common and simplest are using the internal MEMS gyro for RPM and Pump cycles. Some examples of Activation protocols are given below”

For example, a well trajectory that is tortuous and suffers from high torques and stick slip may not be suitable for an RPM based activation protocol. In this case, the tool can be programmed with an RPM protocol but also a pump cycle protocol. If the RPM protocol was not read by the tool due to severe stick / slip, the Pump Cycle protocol can be used. Several protocols can be stored simultaneously in the tool and used at any time.

Pumps and RPM OFF for minimum 120 secs.

80 RPM ON for 60 secs

RPM OFF for 60 secs

80 RPM ON for 60 secs

RPM OFF for minimum 120 secs. AVS should be in Full Bypass position.

Pumps and RPM OFF for minimum 120 secs.

80 RPM ON for 60 secs

RPM OFF for 60 secs

120 RPM ON for 60 secs

RPM OFF for minimum 120 secs. AVS should be in Thru-bore position.