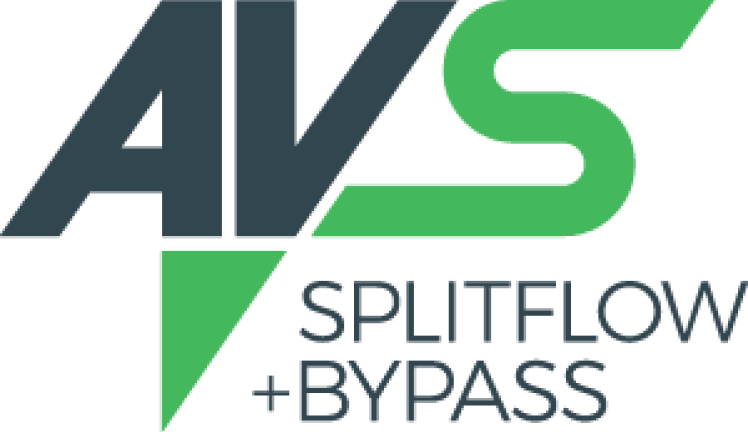

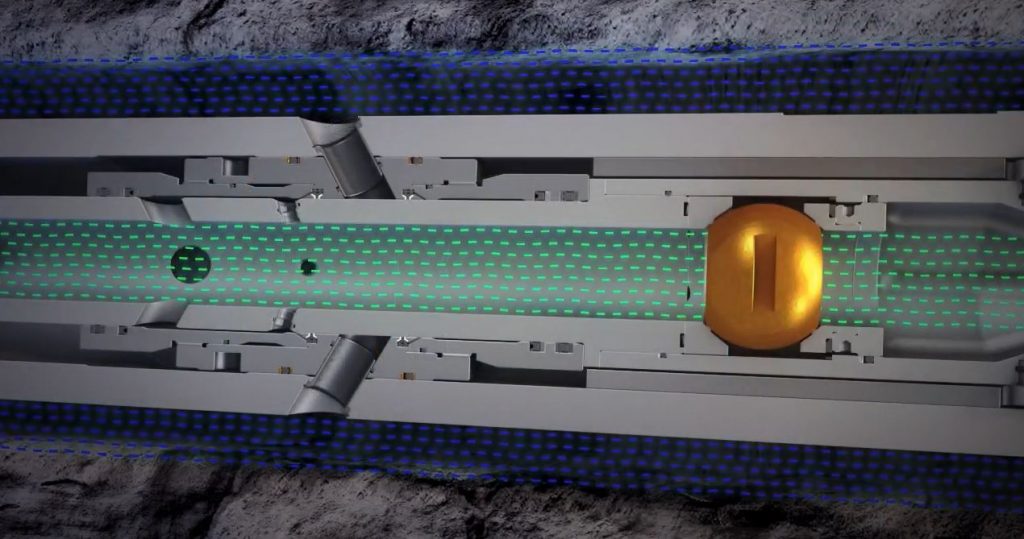

AVS in Thru-bore position. This is the standard position where all the drilling fluid is pumped through the AVS, BHA and drillbit.

The AVS is a DEAP activated Multi-position, Multi-cycle Flow Divertor. It can be run anywhere in the drillstring or BHA, even below an MWD as there are no balls or darts to drop to activate. It has 3 positions; Thru-bore, Splitflow for Hole Cleaning While Drilling and Full Bypass for LCM dump or rapid well

AVS in Thru-bore position. This is the standard position where all the drilling fluid is pumped through the AVS, BHA and drillbit.

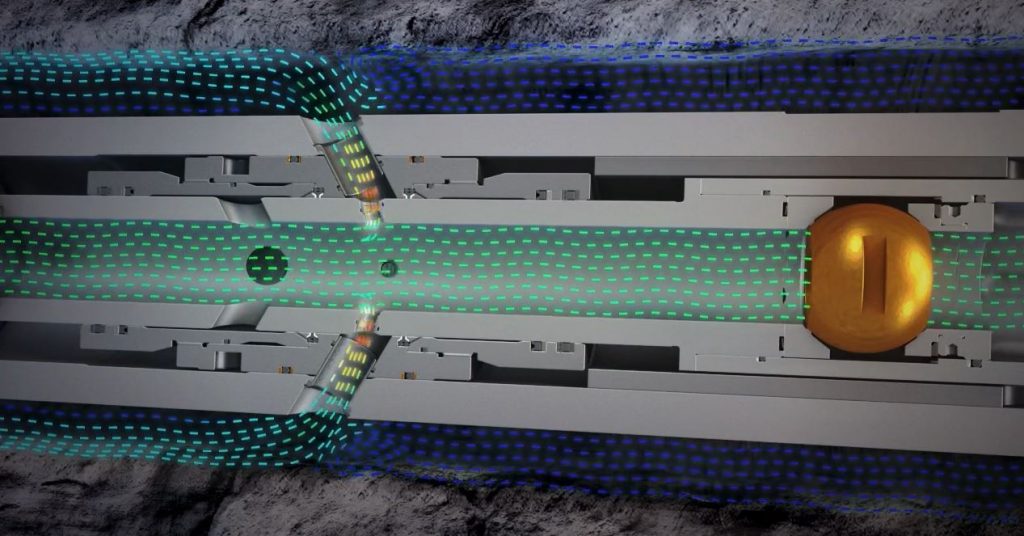

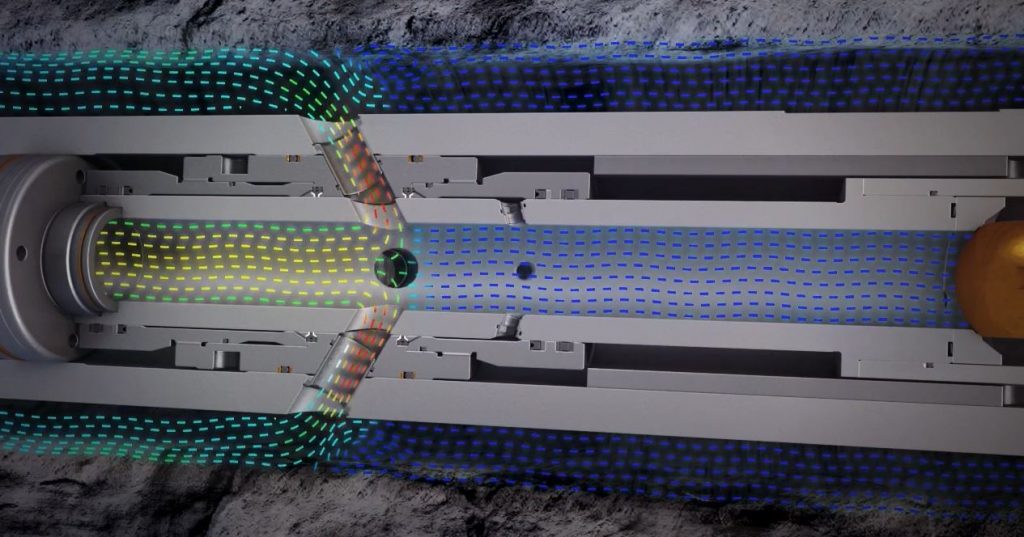

AVS in Splitflow position. A portion of dilling fluid bypasses the BHA, reducing pressure losses, allowing a flow increase, maximising AV.

AVS in Bypass position. 4in² TFA are opened for rapid wellbore clean up or dumping of LCM. A ball valve closes to protect BHA components.

Hole cleaning effectiveness is a function of; Hole angle, Mud rheology, Hole size, Drillpipe size, drillstring RPM, Mud density, Mud annular velocity, Annular eccentricity, Cutting size and ROP. Practical experimentation has shown that the most effective hole cleaning parameters are Mud Annular Velocity and Mud Density. The higher the AV, the more cuttings are removed from the wellbore.

The AVS and AVD can be Nozzled to allow a certain amount of the flow to be diverted into the Annulus, bypassing the BHA. This can be engineered using IDT’s Splitflow software to allow the minimum flow requirement to power MWD / RSS Motor / Bit hydraulics etc, and the remainder out to the annulus. This maximizes Annular Velocity for a given surface pressure.

The 1st chart shows how a Splitflow of 35/65, keeps enough flow going through the BHA (800-600gpm) to power BHA and bit components but the overall flowrate is 20% higher than if all the flow was going through the BHA. The 2nd chart shows the increase in cumulative volume pumped over the example hole section. This is over 37,000bbls additional fluid pumped which means 20% more cuttings removed from the wellbore.

No drop balls, Darts or RFID tags

Command via surface Downlink

Simple and Rapid commands

Throughbore at all times

Battery powered. Low power draw

In excess of 100 cycles

Splitflow position with Variable

Bypass position with BHA shutoff

4in² TFA in full Bypass position

Can be run in any inclination well

Can be activated in horizontal wells

Can be run anywhere in the BHA

Can be run below an MWD

Splitflow maximises Annular Velocity

Up to 200ppb LCM through Bypass

LCM will not enter BHA in Bypass

Cleans hole while drilling in Splitflow

No waiting for Balls and Darts to drop

The AVS has multiple application including:

Maximise hole cleaning while drilling

Pumping LCM

Stabilisers preventing pack offs

Run behind Reamer

Subsea Riser / BOP Jetting

Hole cleaning with Tapered String