Hole Cleaning

Maximise your hole cleaning capability by running the AVS in Splitflow position. This maximises AV, improving Hole cleaning while you drill. This also reduces time take to clean up the well at section TD.

Annular Velocity

What is Annular Velocity (AV) and why does it matter?

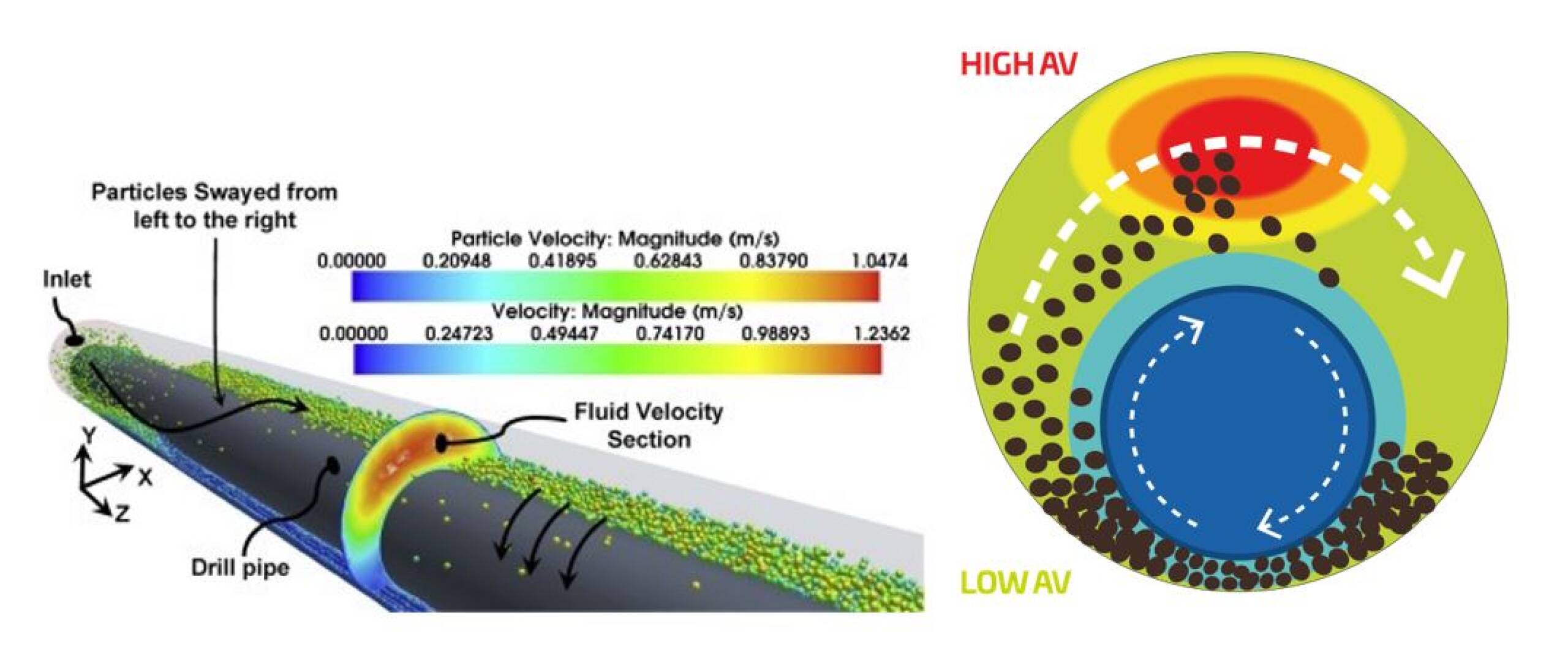

Annular velocity is key to effective hole cleaning. It is one of the three vital elements, the other two being pipe rotation and low-end rheology of the drilling fluid.

The AVS (Annular Velocity System) maximises AV by utilising its Splitflow position. This allows a higher flowrate for a given surface pressure. In general 150ft/min AV is the minimum required in a high angle well, however, hole cleaning efficiency will always increase with increasing AV and >200ft/min can be considered optimal.

Maximising AV allows the high AV band to extend further around the DP as it lies in the wellbore depicted in the diagrams. High RPM of the DP picks up cuttings in the cuttings bed and throws them into the fluid flow for a rapid exit from the wellbore.

Mud weight also has a high influence on cuttings bed formation as gravity is the major reason for cuttings settling to the lowside. If the difference between the cuttings density and the fluid density can be reduced, the speed at which cuttings settle, can be reduced.

SPLITFLOW INCLINED NOZZLES

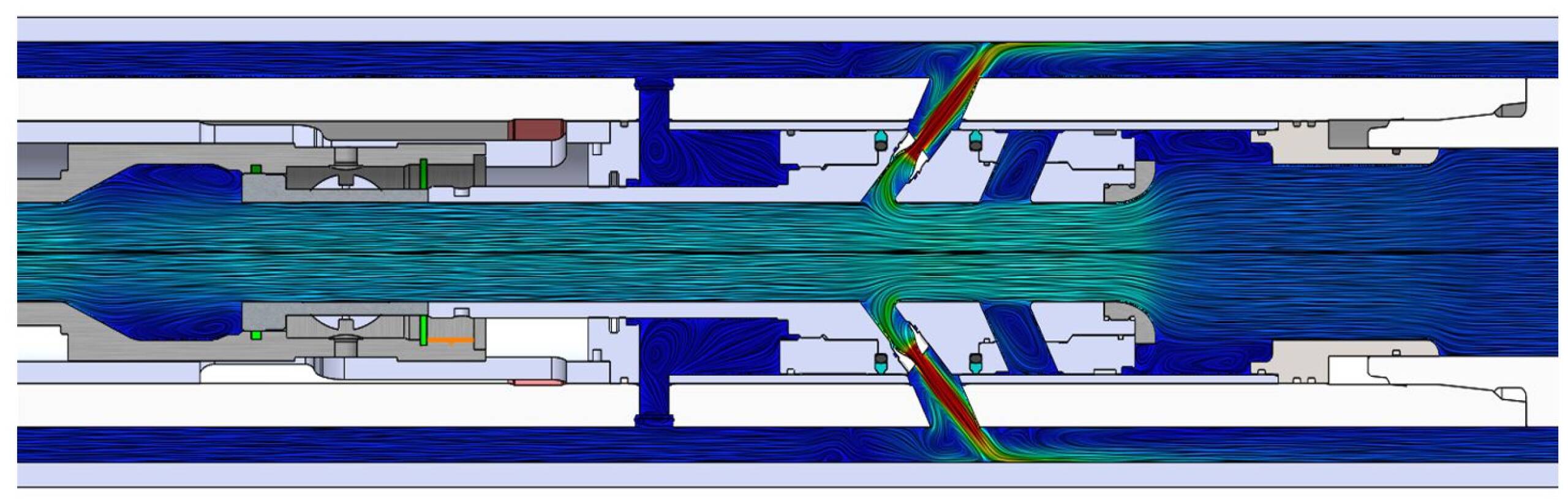

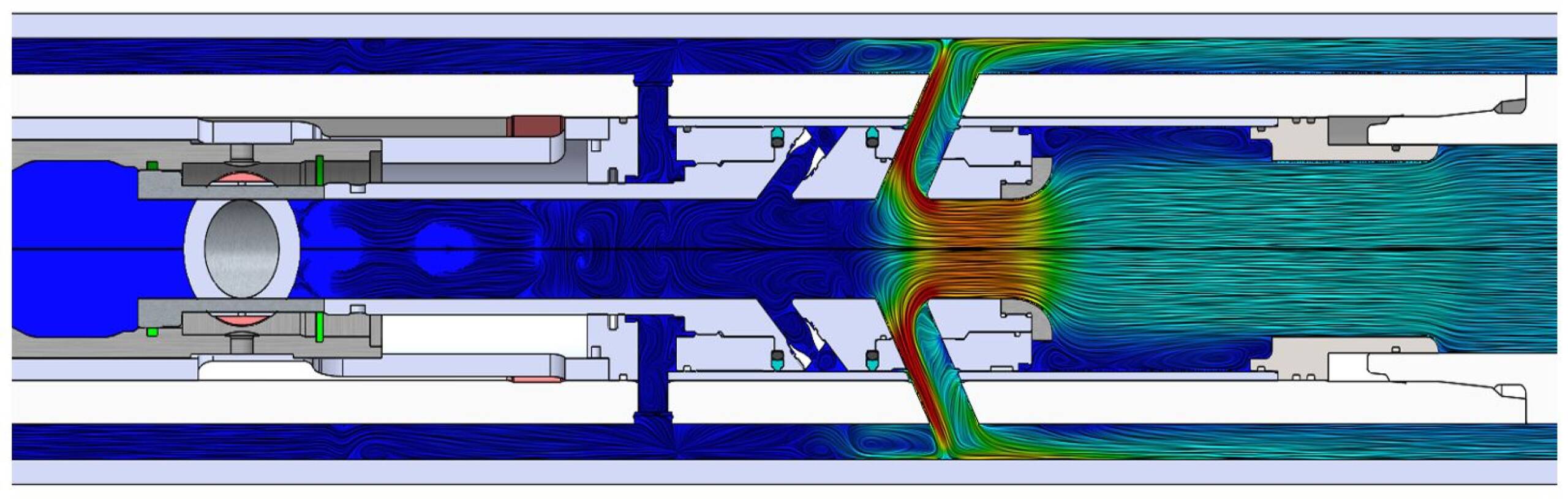

There are 4 nozzles on the AVS that can be changed to suit the particular application and Bit/BHA hydraulics design.

IDT have developed through Computer Flow Dynamics an inclined nozzle design that minimises erratic turbulence around the borehole wall. This ensures that all the flow is going “up” the hole in the direction of flow. Without inclined nozzles, some of the flow exiting the nozzle will try and go down the hole causing extreme turbulence which is not good for hole erosion in sensitive formations.

CFD of AVS flow in Splitflow position

CFD of AVS flow in Bypass position

The video shows an 8” AVS being surface tested. The blue collar around the inclined nozzles simulates the borehole wall. As can be seen 100% of the flow is directed in the direction of the annular flow up the well.